What Are The Top Emerging Trends In Engineering Design Technology?

Engineering design is improving and evolving faster than ever before as a result of rapid advances in technology. Design engineers can now...

Engineering design is improving and evolving faster than ever before, thanks to advances made in technology. Design engineers can now develop versatile designs that make products easier to use – and usher in the future.

If you’re a product design engineer, you’re responsible for creating and developing new products. You’re researching and developing ideas and processes for new products, improving the performance and design of existing products, and overseeing the production and packaging of final products. So, there’s a lot on your plate.

On top of all of this, how companies develop a product is also constantly changing. It can be hard to keep up. Here is an overview of four of the latest trends in engineering design technology that are worth watching.

Now let's take a closer look at each one.

Many people worldwide joke that robots will take over because of how advanced they have become. Indeed, the internet contains many videos of robots doing impressive things, including complex tasks such as dancing.

Robots today are almost life-like, thanks to factors such as versatile engineering design and artificial intelligence. They are not taking over, but they are playing increasingly significant roles in many industries.

Many industries now use robots, including some industries that were traditionally not expected to associate with robots. For example, many restaurants are using robots for roles such as cooking and serving their guests to fill the growing labor shortage. More importantly, they are helping keep supply chains running in many manufacturing industries. Bottom line: robots are a core aspect of humanity's future.

The last thing you want to happen as a product design engineer is for your design to fail. Companies such as car manufacturers have issued worldwide recalls of products and incurred huge losses as a result. Fortunately, you can greatly minimize (and entirely eliminate) the risk of your product designs failing through digital twins technology.

Digital twins technology allows design engineers to design virtual replicas of products in a virtual world. The technology mimics conditions in the real world, essentially allowing design engineers to test the products before expending resources producing them. This technology is now easier and more affordable, thanks to the Internet of Things (IoT).

Generative design technology is one of the drivers behind new versatile product designs, such as the life-like robots discussed above. This technology is using artificial intelligence (AI) to develop new designs that most product design engineers wouldn't otherwise imagine.

The design engineer feeds the program with design parameters and then the AI-powered algorithm generates all possible design solutions. The engineer then tests the varying solutions to select the most feasible one.

Generating design technology is helping break barriers in manufacturing. For example, it is credited with developing the design for the Airbus A320's interior partition – this technology helped reduce the partition's weight by 45%, making the airplanes safer and more economical. Generative design technology is often used in combination with digital twins technology.

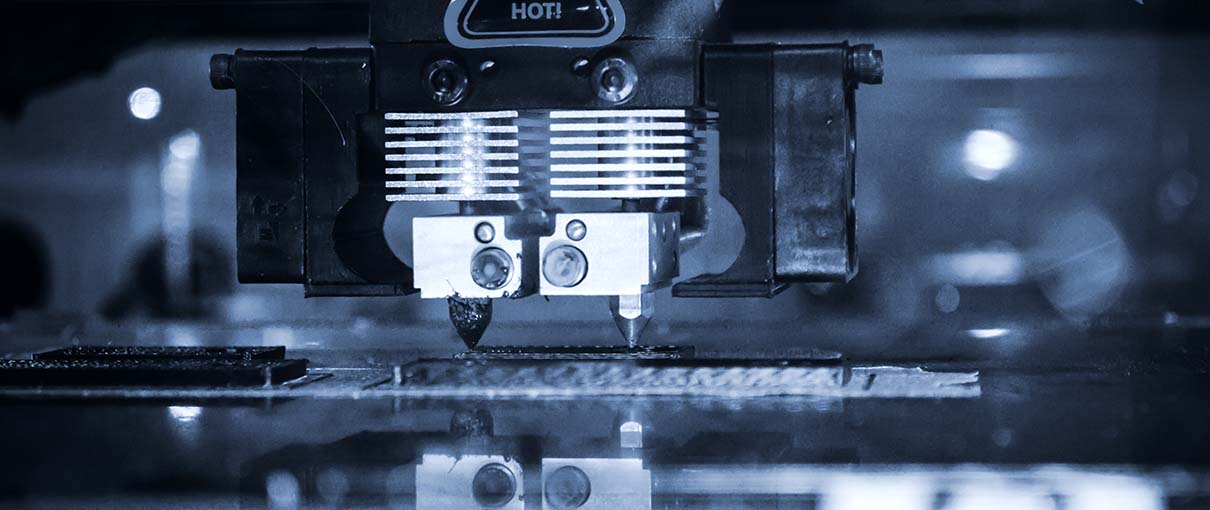

3D printing has been revolutionary for design engineering and many other industries. 3D printers can work around complex product designs, making it easier, faster, and cheaper to develop innovative products. Design engineers simply feed the design parameters into the printer to make a rapid prototype.

3D printing has a wide range of uses and applications for design engineering. The greatest benefit is flexibility in design execution, as explained above. Another noteworthy benefit is that the products designed through 3D printing technology are lightweight and strong, ensuring durable construction.

As mentioned, the last thing any product design engineer wants is for their products to fail. These and other technologies in design engineering help make products better, but the products' overall quality ultimately depends on the quality and durability of the materials used. For example, sub-standard bolts and nuts disintegrate fast, compromising the whole product's integrity.

Big Bolt is the leading manufacturer of high-quality fasteners, including rods, bolts, nuts, and washers. These fasteners last longer than the most durable materials. Visit our website to explore our inventory of fasteners and capabilities.

We can help improve all types of designs. Our staff of full-time quality employees and certified inspectors ensure your fasteners meet your requirements. And our computer-aided tensile testing machines and four automatic Rockwell hardness testers ensure quality.

Project management is a team effort. Let us help you with your next design engineering project.

Engineering design is improving and evolving faster than ever before as a result of rapid advances in technology. Design engineers can now...

Mechanical fasteners are small but integral parts of any product that uses multiple components. They are used to adjoin components,...

Shoulder bolts are popular machine screws with an unthreaded shoulder under the head, more prominent in diameter than the threads. They are...