This Is What Makes Metric Bolts and Standard Bolts Unique

For as long as anyone can remember, man has had measurements for everything from distance to weight. Sizes have since evolved in different...

Tap bolts and structural bolts are considered to be quality fasteners. They’ve been used in the equipment assembly industry for years, but very few consumers can differentiate the two.

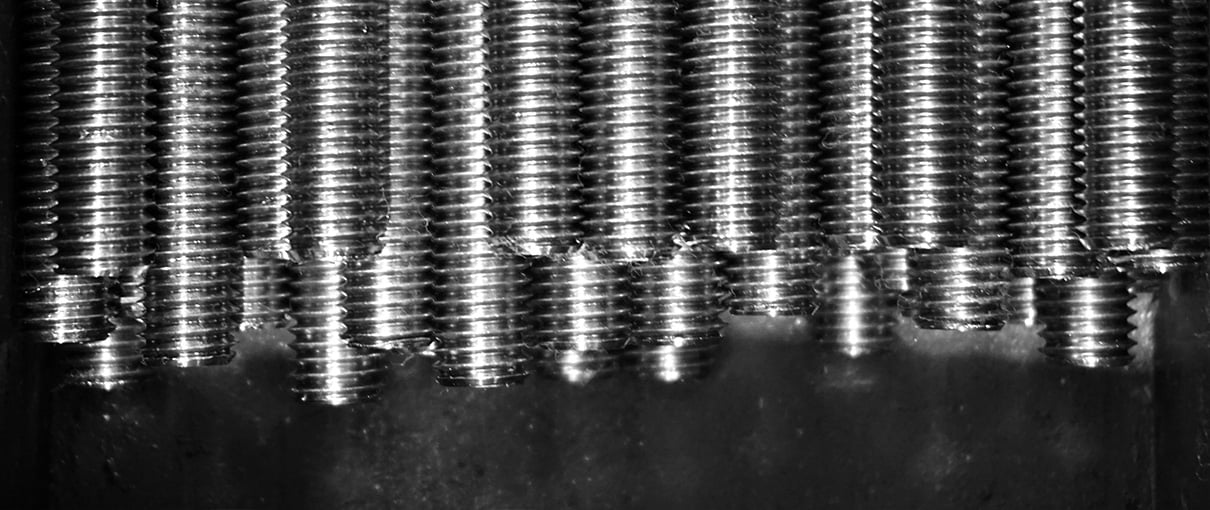

Despite their differences, they bear similarities. Both are used as mechanical fasteners to tightly connect metal parts to create sturdy structures. They also feature threaded shafts and hex heads. A bolt is inserted through an unthreaded hole and mated with a nut, fastened on the threaded end to offer the needed torque to prevent axial movements.

The American Society for Testing and Materials (ASTM) sets the standards for fastening materials used in specific industries or applications. While ASTM sets industrial steel-grade standards, the Society of Automotive Engineers (SAE) grades steel bolts in the automotive sector. Adherence to these standards is non-obligatory, but many bolt manufacturers conform to them to build trust and authority among their consumers.

So, what are the differences between tap bolts and structural bolts? This article discusses how the two differ in design, grade, and application.

Tap bolts usually feature a fully-threaded shaft, and users can use two fastening techniques to tighten them: They can be inserted in holes and a nut torqued on the other end to provide the required clamping force. On the other hand, it can be mated with an internally threaded/tapped hole. In the latter technique, a nut may or may not be used.

The threads are standard clockwise-fastening and run throughout the bolts' length. Additionally, they have Unified National Coarse threads. Combined with their relatively longer shafts, they are the ideal fastening tools when working with materials of extended thickness range. Furthermore, the extended grip also results in a "springier" bolt, enabling tap bolts to absorb vertical forces.

Hex tap bolts fall under SAE Grades 2 and Grade 5. The former matches ASTM A307 with diameters ranging from ¾" to 6". Due to their low-carbon-steel construction, they can withstand compaction forces up to 60,000PSI. Grade 5 bolts are equivalent to ASTM A325 bolts but are engineered using medium carbon steel, boron steel, or weathering steel. That gives them a higher tensile strength of 120,000 PSI. For a project's success, it's critical always to ensure you use the same nut grade as the bolt grade.

Their full-threaded design renders them versatile and can be used in a wide range of light repair and maintenance applications. For instance, they're used in the automotive repair industry to attach motors to machinery and pulley systems for adjusting belt tension.

Also known as high-strength bolts, structural bolts are hex-head style threaded fasteners used in heavy-duty applications, such as connecting steel beams in metal building frameworks. That said, they are typically shorter than tap bolts. Still, they and must also meet specific ASTM standards. The ones used in heavy connections include ASTM A563, A325 (Grade 5), and A490 (Grade 8), typically indicated on the bolt.

While tap bolts are commonly Grade 2 and 5, the commonly used structural bolts are Grade 9 and 8 bolts. The former is ideal for heavy-duty applications as it provides a tensile strength of 180,000 PSI. They are often used in pieces of heavy machinery, such as bulldozers. Unlike tap bolts (standard zinc-place finish), Grade 9 bolts are polished using yellow zinc chromate that bolsters their corrosion resistance.

Grade 8 is the highest grade for an SAE grading scale, and its equivalent is the ASTM A490 bolt. They differ from tap bolts in construction material. Instead of using medium carbon, bolt manufacturers use steel alloy for SAE Grade 8/ASTM A490 bolts, providing a significantly higher tensile strength of 150,000 PSI.

Understanding the right bolt to use for specific applications is critical. Choosing quality fasteners will give you peace of mind knowing that you’re developing high-quality products and steel assemblies. This alleviates both internal and external product failures. It cushions you from incurring costs of poor quality, such as product redo, quality inspection costs, and wasted labor. On the consumer side, you avoid expenses, such as warranty claims, complaints about part quality and workmanship, and rapid product deterioration.

Contact Big Bolt today and purchase high-quality fasteners, including bolts, nuts, and screws for a successful project.

For as long as anyone can remember, man has had measurements for everything from distance to weight. Sizes have since evolved in different...

Shoulder bolts are popular machine screws with an unthreaded shoulder under the head, more prominent in diameter than the threads. They are...

Bolts and cap screws are both essential fasteners that are used in a wide range of applications. While they may seem similar, they have...