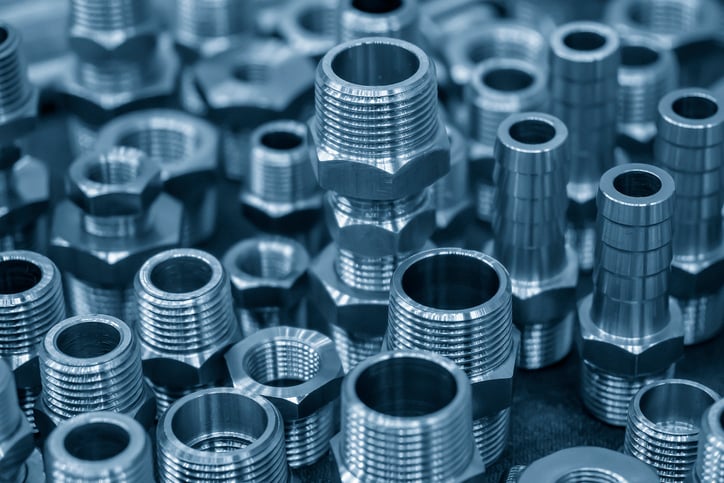

Important Mechanical Properties For Threaded Fasteners

Threaded fasteners are crucial in any design work. They’re used to hold components together. But getting quality fasteners can be a chore...

Threaded fasteners are crucial in any design work. They’re used to hold components together. But getting quality fasteners can be a chore unless you pay attention to the mechanical properties of materials your fasteners possess.

The mechanical properties of materials define how your threaded fasteners behave when they’re subjected to external forces known as loads. For joint designing, fasteners are covered by criteria and specifications that define the required mechanical properties of materials such as

And studies show that the best-threaded fasteners should not only be able to hold devices down during operational loads but should also be able to withstand extreme loads, too.

We've put together this list to help you better understand what you should be looking for. It breaks down some of the most important mechanical properties of materials when designing threaded fasteners.

Tensile strength vs yield strength. It's an age-old debate. But which stands out when it comes to threaded fasteners? Tensile strength is stress measured as force per unit area. It’s the maximum load that a material can support without fracture when under tension. Threaded fasteners are tested on tensile testing machines to validate tensile properties that meet the appropriate strength grade. When buying threaded fasteners, you want to check SAE J429 (imperial sizes) and ISO 898-1 (Metric sizes) to determine the required mechanical properties for your project.

Materials are often deformed when some level of stress is applied to them. So, the best way to know how much a material can yield before it’s permanently deformed is to check its yield strength. A bolt’s yield strength is defined as the tensile force that causes a certain amount of permanent deformation within a fastening.

The proof load is the maximum tensile force applied to a bolt without causing plastic deformation. The optimal material proof load should be between 85% and 95% of its yield strength.

The University of Southampton defines hardness as the resistance of a material to localized plastic deformation. Hardness varies from one material to another. Some of the hardest materials are diamonds and boron-carbide. On the other hand, plastic is considered a soft material.

When looking for threaded fasteners, product designers should always be cautious. The ability of a material to resist forces that cause its internal structure to slide against itself is known as shear strength. For lifespan, the ideal ones should have a high shear strength.

Shear strength is often measured horizontally, in single or double shear. Two blades with centrally positioned transverse holes are used in a single shear test. One blade holds the fastener in position while the second blade shears the fastening in a parallel plane. In double shear testing, second stationary blade support is placed behind the shearing blade.

Fasteners for joint design are covered by standards that define required mechanical properties. Making the right choice of threaded fasteners can save you money in the long run because they will stand up to the pressure.

Big Bolt manufactures high-quality ISO and ASTM standard fasteners. If you’re looking to shop for some, we’ve got you covered. With experience in service industries like aerospace, agriculture, construction, industrial, and maritime, be sure to contact us if you have any questions about your next project.

Threaded fasteners are crucial in any design work. They’re used to hold components together. But getting quality fasteners can be a chore...

Screws, nuts, bolts, rivets, pins, and collars are common fasteners in the aerospace industry. But aerospace fasteners are frequently ...

Screws, nuts, bolts, rivets, pins, and collars are common fasteners in the aerospace industry. But aerospace fasteners are frequently ...