Why CNC Machines Are Needed To Make High-Quality Fasteners

Due to their tremendous capabilities, CNC machine tools are utilized in various sectors to make endless high-quality fasteners. It can make...

When the time comes to purchase fasteners for your project, you can’t sacrifice quality. A fastener supply company can deliver custom orders in a day if needed, but you deserve to have all of your needs met.

While a manufacturer's inventory and capabilities for tight turnarounds must be considered, be sure not to overlook the method by which the tools are being built. With a manufacturing partner experienced in CNC machining, you can be sure you won’t sacrifice precision for speed.

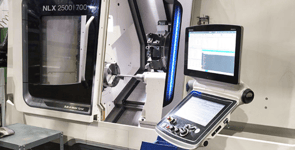

Computer Numerical Control (CNC) is an automated process that uses a computer to perform the process of Machining engineered fasteners and other close-tolerance work on a production-based schedule. The computer uses specifically designed software using a language called G-Code that is used to control the actions of the tool.

Working with a fastener supply company that has an established CNC Machining workflow is critical to sustaining long-term success in any business sector with demand for the product.

Riding the wave of the Digital Revolution, the process of using tools to machine nuts and bolts has evolved rapidly over the last several decades. While it may seem like a distant memory that all of these tools were made by hand, some providers still use traditional machining methods. Computerization has created a more sustainable and productive workflow while simultaneously eliminating room for error. Every detail is programmed ensuring your specifications are upheld.

The industry applications for products made with CNC Machining technology are diverse. Just as diverse as the industries are the materials that can be used in these processes. From popular options like stainless steel to virtually any other material that suits your needs; lathes, routers, grinders, and mills operated by CNC Machining technology are expertly crafting high-quality fasteners quickly and accurately.

Having a productive CNC Machining workflow in place can really set your fastener supplier apart from the pack. Gaining access to a company that has a rich inventory of high-quality fasteners in a variety of materials, as well as the ability to create custom nuts and bolts can make the difference in your next project’s success.

At Big Bolt, we have a dozen programmable CNC machines. This allows our operation to maximize productivity and deliver even the most complex fasteners with expert precision, ensuring quality. With an impressive inventory ready to ship immediately, even emergency orders can be satisfied right away.

While our inventory is made up of; bolts, studs, rods, nuts and washers that were made using mills, lathes, routers, or laser cutters operated by way of CNC Machining, Big Bolt can also meet your most challenging custom requests. CNC Machines operated by our highly-trained and certified employees are expertly programmed to meet your distinct requirements while maintaining the high-quality standards we’re known for.

Big Bolt can produce prototypes for approvals and quickly transition into producing large volumes with superior consistency. With this system in place, we can turn around most orders within a day, large-scale orders of 10,000+ fasteners in a few days - not weeks.

Take the guesswork out of your fastener supply chain. Big Bolt is the leading manufacturer of high-quality fasteners that are built to last.

When it comes to custom designs, our team is capable of meeting or even helping improve your specifications to meet your requirements to ensure your products never fail.

That’s why Big Bolt uses CNC machining technology that can guarantee the precision you need. Embracing technology that enables quick turnarounds while maintaining industry standards for quality is a win-win.

With no minimum quantity requirements to purchase, talk to an expert today about solutions for your business.

Due to their tremendous capabilities, CNC machine tools are utilized in various sectors to make endless high-quality fasteners. It can make...

Good quality fasteners make project management easier and safer. The best fasteners don't just come by — they're made using the right...

A fastener supply company relies heavily on the supply chain, which is a term that is gaining a lot of popularity but for all of the wrong...